In all fiber optic systems, it is necessary to join two fibers together with low signal attenuation while maintaining low reflection levels depending upon the type of system used. Fiber optic connectors are used to the mechanical and optical means for cross connecting fibers and linking to fiber optic transmission equipment.

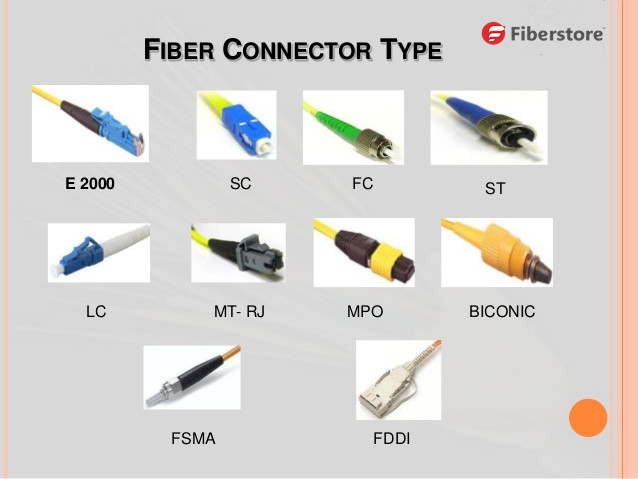

Connectors have evolved with the communications industry. Today’s users have a multitude of connectivity needs and the fiber industry has responded with innovative solutions. The most common connector in use today is the SC connector, the ST connector and the FC Fiber Connector. In addition the small form factor LC connector is used in high-density optical transmission products, and also for applications including fiber-to-the-home and dense wavelength division multiplexing where space is at a premium. Another connector gaining in popularity for use in high fiber count terminations is the MPO/MTP connector which can handle fiber counts as high as 96 using ribbonized fibers.

To understand fiber optic connectors one must understand both the mechanics and the optics involved. The ideal optical connector holds the fibers in perfect alignment, in three axes. This alignment must be maintained over hundreds or even thousands of connect-disconnect cycles to provide stable, repeatable attenuation characteristics.

The most important element of the connector plug is the ferrule, which provides the precise alignment and centering of the optical fiber. Ferrules can be made of ceramic, metal, glass or plastic. Zirconia ceramic ferrules or ceramic ferrules with metal inserts are most widely used, providing the best tolerances and durability. The most common ferrule sixes are the 2.5 mm used in the SC, ST, and the FC plugs. The 1.25 mm ferrule is used in the small form factor LC plug. For connectors designed for military and aerospace connectors the “termini” performs the same functions as the ferrule and are provided as both pin and sockets. Common connector types have SC connector, ST connector, FC connector, ect.

The body of the plug holds the ferrule, the coupling mechanism, and the boot. The body contains either a threaded, push-pull or bayonet coupling mechanism that mates the plug with the mating adaptor and also provides a keying function that allows the connector to mate in only one position. Strain relief of the cable is usually by a crimp sleeve or by adhesives which firmly secures the aramid yard in the cable to the plug body. At the rear of the plug body is the “boot” which functions as a bend radius limiter for the cable entering the plug body.

Another critical component is the mating adaptor, and its internal sleeve that aligns the two mating ferrules. Like the ferrule, sleeves are most often made from ceramic and can be either a split or solid construction. The alignment sleeve must precisely align the two precision ferrules by means of the ferrules outside diameters. This alignment must be done while providing a low-friction fit over a wide temperature range.

Over the years, fiber tolerances have greatly improved along with the mechanical tolerances of precision parts of the connectors.Early connectors suffered from poor alignment tolerances and mechanical stability problems due to loose fiber tole rances and mechanical tolerances of the connector design. The body and mating adapter also provide a keying function allowing the connector to mate in only one rotational position. This, combined with the tight tolerances of today’s optical fiber, ensures compliance with the Telcordia GR326 generic requirements repeatability standard of less than 2 dB connection loss over 500 mating cycles for single-mode fibers.

Today most lensed connectors work by expanding the beam exiting one fiber, then collimating the beam to the adjacent plug where a second lens is used to collect that light and re-direct it to the core of the second fiber. The main advantage of this approach is that the connector is less sensitive to alignment tolerances, so attenuation will remain more constant in the presence of vibration or temperature cycling. In addition the large area of the beam minimizes the impact of contaminants. The largest supplier of multi fiber expanded beam connectors are developed and manufactured by TE Connectivity and are provided in many variations for harsh environments such as mining, military, and aerospace applications.

Note: Fiber Optic Connector is an important components used in the fiber optic network. It is also the key part used in fiber optic patch cord and fiber optic pigtail. There are many kinds of fiber optic connectors. We supply one piece fiber optic connectors various types, including standard connectors and irregular types, epoxy types. we supply fiber optic types include: SC fiber optic connector, FC fiber optic connector, ST fiber optic connector, LC fiber optic connector, MU fiber optic connector, SC/APC fiber optic connector, FC/APC fiber optic connector,etc. Both Single mode fiber optic connector and multimode fiber optic connector available.